~ QUAD 303 'Lab Amplifier' with volume control ~

In 2008 I took a QUAD 303 amplifier and 33 pre-amp as part exchange against some work on a QUAD 405 which I modified to my DCD–Mod3 with an input gain control for use in a studio ~ The QUAD 303 was a 303A2 which was the BBC modified version for driving the BBC LS3/8 loudspeaker and should have been fitted with an active crossover in a tray under the amplifier base

The QUAD 303 arrived but did not have the crossover fitted and had been modified with 4mm speaker sockets whereas the BBC 303 A2 output would have been via a 5 pin 'XLR' connector which was still fitted ~ I like the QUAD 303 and because this 303 A2 had a handle fitted to the top I thought it would make an excellent general purpose 'Lab Amp' especially if fitted with a front panel input attenuator [volume control ]

When I say 'Lab Amp' I mean a general purpose audio power amplifier that can easily be put into service at short notice to test other equipment and one which does not take up too much shelf space or require careful handling when carried around and has predictable and repeatable performance from the input attenuator

The 303 has a capacitor coupled output which makes it safe for connecting to other peoples speakers in unknown systems and the addition of an input gain control would enable direct connection to CD players or iPhone etc ~ A gain control with indents to enable known set attenuation would be very useful

The QUAD 303 was not QUADs first transistor amplifier ~ The QUAD 50 was a push pull transistor design with a multi tapped output transformer aimed at professional users due to its high cost and odd connections ~ An interesting point about the QUAD50 and the QUAD303 is that they were intentionally made the same size as the QUAD II valve amplifier and had their input and output connections at one end

With their connections grouped at one end the QUAD II QUAD 50 and QUAD 303 could easily replace each other in professional fixed installations ~ It also saved on packing boxes with later QUAD IIs being shipped in QUAD 303 boxes with polystyrene inserts ~ but for me it would make my QUAD 303 Lab Amp easier to operate with all the connections and the attenuator at one end

The QUAD 303 A2 was in reasonable condition and tested okay apart from a damaged fuse holder ~ but as usual the PCBs in base had collected layers of dust and dirt over the years

The easiest way to clean the PCBs in situ is to hinge them down and wash them over a sink making sure not to wet the transformer ~ I used a hard spray of Mr Muscle kitchen cleaner as seen in the picture followed by hot but not boiling water and then dried the PCBs with a hair dryer

While drying gently turn the 5 pots on the PCBs each several times to the ends and then to centre

The pot on the regulator PCB did not readily adjust to give a steady 67Vd.c. supply as measured at tags 1 and 9 on the amplifier PCBs so a better pot was fitted to set the 67V which was then removed and replaced with a fixed resistor ~ RV100 on each Amplifier PCB were adjusted to give <33V between tag 5 and the output 0V GND terminal

Adjusting the output d.c. for exactly ½ the 67V supply makes the signal clip symmetrically but clipping asymmetrically generates even harmonics which should sound better if this could be tested ~ The bias was adjusted for minimum distortion @1kHz which was around 0.004% on both channels and as adjusted all 4 pots were at the middle of their range which suggests QUAD got it right

The cheap 4mm connectors that had been fitted were replaced with Binding posts connected directly to the new 2200µF 100V Philips capacitors with the resistors R1L and R1R moved to the sockets

The new input phonos and binding posts were mounted on a 5mm plastic panel at the front so the side holes of the output terminals cleared the front casework

Extra 4.7µF poly caps were fitted across C1L and C1R ~ click on them to see why

Apart from replacing the electrolytic capacitors and changing C100 to the orange 1µF BC polypropylene ones and fitting an additional 4.7µF capacitor across the regulator output no other deviations from the original design were made ~ 2200µF 100V for the output capacitors and the same paralleled for the power supply smoothing are more than adequate

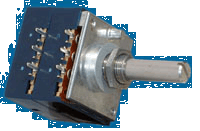

I did look at increasing the input impedance by making R101 larger so that a 50kΩ pot could be used for the input gain control but this would worsen the signal to noise ratio for mid to low gain settings so I investigated the effect of loading a 10kΩ log pot with the 22kΩ of the QUAD 303 input impedance ~ I had some 10kΩ ALPS 27mm stereo log pots with 41 detent positions which measured:

| Position | Load 1MΩ | Load 22KΩ | Difference | +3kΩ | Difference |

|

10

9 8 7 6 5 4 3 2 1 0.5 0 |

0dB

–1.0 –3.7 –7.8 –12.8 –16.6 –22.2 –29.8 –38.9 –53.9 –70.0 –99 |

0dB

–1.4 –4.6 –8.7 –13.8 –17.2 –22.5 –29.8 –39.0 –54.0 –70.0 –99 |

0dB

–0.4dB –0.9dB –0.9dB –1.0dB –0.6dB –0.3dB 0dB –0.1dB –0.1dB 0dB 0dB |

0dB

–1.1 –3.8 –7.6 –12.5 –16.0 –21.8 –28.6 –37.6 –52.6 –69.0 –99 |

0dB

–0.1dB –0.1dB –0.2dB +0.3dB +0.6dB +0.4dB +1.2dB +1.3dB +1.3dB +1.0dB 0dB |

The rotation is from 0 which is fully anticlockwise with each step being 4 'clicks' or detents with the first 2 detents recorded as 0.5 ~ Note the log law of the ALPS pots is made from 4 linear sections with differing slopes as almost all log potentiometers are ~ The column 'Load 1MΩ' shows the intended law for the ALPS 'Log A' type volume control

Having never done this exercise before I was very surprised that the difference between the high 1MΩ load and the low 22kΩ load was as little as 1dB ~ The source impedance for these tests was 5Ω output from an HP35670A so I checked the results with a higher source impedance by placing resistors in series with the AT 35670A generator

Results from one of these test runs with a 3kΩ resistor in series with the 'top' of the 10kΩ pot are shown in table on the right ~ With a 10kΩ potentiometer in parallel with the 22kΩ QUAD 303 input impedance the load would be about 6.8kΩ at maximum and 10kΩ at minimum and would move between these values as the volume is varied

With 3kΩ in series the input impedance is about 10kΩ at maximum and 13kΩ at minimum and the gain variation is less dependant on the output impedance of the source device which ~ with the predictable detents ~ allows better subjective evaluation without measuring equipment so I fitted 3kΩ series which did not affect the S/N ratio much

Testing the almost finished amplifier showed a difference between channels which was traced to the insulation on the output capacitor C1L being split so this was fixed with the green NATO grade silicone finish gaffer tape as shown

This repair actually made the crosstalk worse because the isolated can of the capacitor was now capacitively coupling to the adjacent input pot and its wiring

The ALPS 27mm pot has a screen between the sections which connects to the front metalwork but the case is made of blue plastic [not velvet] so the rear section especially is open to pick-up from adjacent signal sources like C1L in this 303 or mains wiring in the QUAD405 ~ A cure is to cover the case in 25mm wide copper tape which is connected to ground to prevent the capacitive pick–up ~ Note the additional ground connections from the front panel to the main chassis ~ The un-shielded input wires were run between the pot and front panel and did not show any sign of noise pick–up

Testing the QUAD 303 A2 to determine the value of the series input resistors for the gain pot

The table above was measured using an Agilent A35670A ~ seen in the right background ~ which is very accurate for such relative tests

Although the A35670As ultimate accuracy was not required here ~ being able to see multiple measurements for both channels at the same time was very useful

Tests were also made with a Tektronix AA501 and SG505 as seen here in the left background ~ The signal was connected to the input pot via a series resistor [3kΩ eventually chosen]

Monitoring the analogue outputs of the AA501 on a scope often helps reveal some intermittent problems such as the insulation failure of C1L mentioned above and noisy pots

With the binding posts mounted on the 5mm plastic panel large diameter cables and 4mm plugs can be fitted in the side of the posts as shown ~ The panel also covers the large 5pin DIN socket hole where the phono sockets are now mounted

The spacing between the output binding posts was made the 'standard' 3⁄4 inch or 19mm and although this is very close it enables moulded body audio patch leads to connect as shown

The mains input socket is the original LNE variant of the XLR connector reflecting the BBC heritage of this QUAD 303–A2 and the red gain control knob is from a 1970s BBC control panel so looks like it belongs ~ But missing is the red LED power on indicator ~ A BBC requirement which indicated the power supply was present not just the mains input

The mains input socket is the original LNE variant of the XLR connector reflecting the BBC heritage of this QUAD 303–A2 and the red gain control knob is from a 1970s BBC control panel so looks like it belongs ~ But missing is the red LED power on indicator ~ A BBC requirement which indicated the power supply was present not just the mains input

~ QUAD 303 Power Amplifier Volume Control mod ~

On the left is a standard QUAD 303 which already had a volume control fitted by someone else ~ Note the small control knob between the voltage selector and the mains fuse ~ Not a good place for signal wiring

I was asked to modify this amp ~ which was not working due to failure of the 1960s output capacitors and some previous bad PCB repairs

The plan was to replace all the electrolytic capacitors ~ repair the fault and fit an ALPS 27mm volume control in place of the 16mm one ~ The amp was for use in a small sound studio where the mains input would best be a BBC LNE type [as shown above] to fit the rest of the ex BBC equipment bay wiring

First thing to do was to repair and test this QUAD 303 then clean it up ready for the new volume control or input attenuator

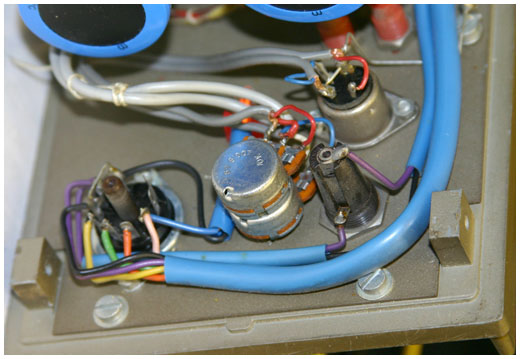

On the right the amplifier with new PSU and output capacitors fitted ~ The regulator and right amplifier board needed some new transistors ~ The 303 was then tested prior to changing the other capacitors or cleaning up the bad track repair to the left channel board

As shown the amplifier tested to specification and the boards were un-soldered and removed to clean them and replace capacitors and tidy up the wiring loom damage from several previous repairs ~ After replacing the reworked boards it was found that the bias and offset pots also needed changing because their set adjustment was not stable and there were some dead spots around the ideal settings

On the back of the front panel the 'original' volume control nested between the mains selector the neon indicator and the fuse [A bad position for electrical safety]

The DIN input is close to the mains wiring and even without a volume control can pick–up mains hum ~ but when driven from the low source impedance of a good pre–amp this is not audible

The volume as originally fitted was known to pick–up audible mains noise ~ mainly from the neon indicator ~ It was this problem and seeing my screened ALPS pot that lead the owner to have this amplifier modified

The new 27mm 20kΩ log pot was fitted where the neon indicator had been ~ the rectangle slot for the neon was rounded out and a new neon fitted the round hole where the old pot had been ~ Rather than rewire the new neon I removed the original neon and resistor and fitted them into the case as shown ~ this made the overall depth about 12mm less with no exposed connections

New input phonos were wired parallel to the 4 pin DIN and a BBC LNE mains socket fitted nicely in place of the Bulgin socket

The finished QUAD 303 with BBC control panel knob and phono input connectors ~ The original silver plated output connectors were not to be replaced and they cleaned up well

There was no audible hum from this arrangement although the phono inputs are close to the mains voltage selector which I had considered removing like the BBC 303A2 build that was hard wired for 240Vrms

If the phono connectors were mounted lower down they may pick–up crosstalk from the output capacitor cans and may need additional screening but they were shrouded from the mains

" Well I don't really care ~ If it's wrong or if it's right "

![[keith-snook.info]](stuff/keith-info-S.png)