~ QUAD ESL63 Loudspeaker Problem leads to Modification ~

In May 1996 I purchased a black pair of ESL63 loudspeakers from QUAD and as my wife often reminds me they cost much more than I should have spent and they take up a lot of space ~ Within 6 months they developed an intermittent fault where the frequency response of one side 'changed' and the otherwise excellent stereo image appeared to shift around and in my room as if one speaker was being raised and lowered !

The speakers were sent back to QUAD which cost a lot in postage although they did return them for free ~ They said the fault was the HT power supply which was replaced under warranty ~ When you have a pair of ESL63s and friends interested in Hi-Fi you find they get borrowed a lot and by 1997 when we moved housed they were looking 'a bit tired' with torn grille cloth and a dented front and worse still the same intermittent fault was back

The ESL63 boxes which had been stored in the garage were not in a good condition so in August 1997 I arranged to take them personally to Huntingdon ~ QUAD service manager Rob Flain said that the service department would again look at the fault and could restore them to 'as new' condition for only 40GBP per speaker plus any parts required and would ship them to my new address in new boxes ~ Excellent I thought

QUAD 'looked' for the fault and ~ although I pointed out a clear foreign object in the area of the problem ~ they returned the speakers to my new address with new cloth grilles and boxes which cost me almost 300GBP ~ They found no fault and as I listened to them for several months they appeared okay

Due to decorating the new home and having a new job the ESL63s were put back in their boxes and ~ because I had borrowed a pair of Tannoy SRM10s for a while and I had my LS3/5A mods plus other speakers coming and going including ESL57s and several pairs of QUAD 11s ~ they were only used occasionally up to 2008 when after a few months they showed signs of the intermittent fault once again

In September 2008 the problem became very persistent so I contacted QUAD ~ now IAG ~ and again spoke to Rob Flain and arranged to send my speakers to their new workshop in Huntingdon along with a letter with pictures of the "foreign object" in the centre panel and copies of my previous letters

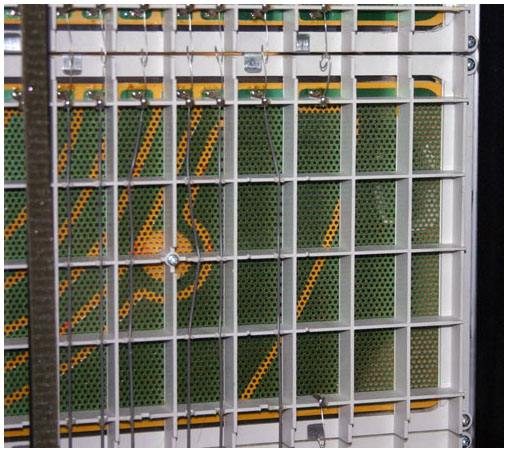

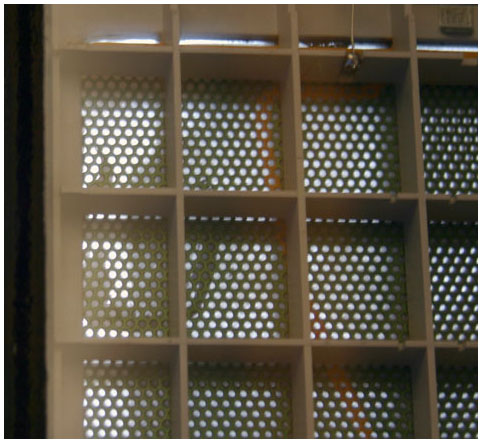

IAG service department said they could not fault the speakers and as you can see from the picture apart from the 'metallic' object at top right the panels and dust covers look brand new

This time I insisted they at least soak test the speaker I had photographed and marked and this they did for several days

I then got a call from Rob Flain who said the panel was 'fluttering' and should be changed and this I agreed to as they said they would discount the parts

View from other side of panel ~ It looks like some surface coating has come free of the membrane and it may have been like this from new

My ESL63 speakers were returned and when I called about the problem with the faulty panel and asked if I could have it back ~ I was told that no one had looked at it and it had been 'thrown in the skip' as soon as removed [more like thrown on ebay]

I was a bit disappointed that IAG do not analyse such odd problems and feed back information into the design or production process but then they have not had in house design since the mid 90s and were being run by an accuntant

Unfortunately in January 2009 the original 1996 problem came back yet again so I contacted Rob Flain at IAG service who suggested that I should return them ~ I was now becoming very frustrated with this persistent problem and decided to look into it myself ~ IAG said they had checked all the panels and power supplies which I trusted so what else could be the cause of the problem ?

Looking over the schematic 2209~2~63 supplied to me by QUAD in 1997 as the correct issue for my speakers there are a number of possible causes:

The 2 transformers L14 and L15 would be tricky to test so were initially ignored

I had never liked the idea of the 220µF input capacitor C25 and why the 1.5Ω resistor R15 ?

Triac T1 is provided to clamp the input if the HT arcs as detected by an aerial wire into Tr3

Polyswitch fuse FS2 operates if T1 operates or if subjected to continued high level input

The protection diode array D26 to D37 could be the cause and is easily disconnected but IAG should have seen that

There's the delay line where I would like to see high voltage poly Cs in place of the ceramics C1 to C13

Then I noticed a 1.5µF 100V capacitor behind R1 and R2 but could not find it on the schematic

I called Rob Flain at IAG and asked about the capacitor which was not on the schematic I had been given and the conversation led to the fact that the service department were using the same issue schematic as me ~ Some days later I received in the post a photo copy of an updated schematic 2209~4~63 and a note from Rob Flain explaining some questions I had asked:

"I think the resistor capacitor combination has more than one effective use.

At low frequencies it makes a 1.5 ohm series resistor thus slightly reducing output below about (guessing) 3kHz. This is most likely matches partly the effect of the capacitors in the terminating resistors of the delay line that make the whole voltage appear across all the elements for LF.

The 1.5 ohm also protects the amplifier if the spark detector kicks in and crowbars the transformers, at least the polyswitch has time to heat up and save the day."

Rob Flain, IAG Group Service Manager, IAG Group Service . . .

I understand the 1.5Ω R15 protecting amplifiers from the T1 crowbar short and also from low frequency excursions at amplifier switch on or due to footfall where the impedance of the input transformers is less than 4Ω ~ Footfall occurs during vinyl record playback where low frequency excursions are produced by the cartridge as people walk across suspended floors near the turntable and I'm sure it was noticed as a problem during development of the ESL 63 as fuses in the QUAD 405 were blown

The capacitor C25 must simply be to maintain the input sensitivity in the audio range ~ It is difficult to model the effect of the R15 C25 combination because the input impedance is high and variable in the region up to 500Hz where the combination 'turns over' ~ There is NO benefit fitting a ridiculously large 220µF polycap it is better to simply bypass C25 with a polycap

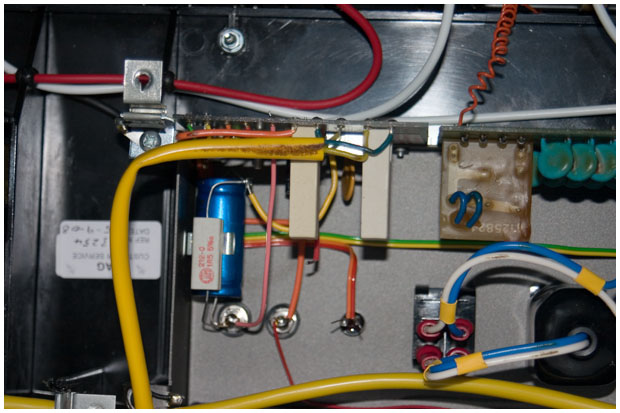

My first test was to bypass R15 and C25 and FS2 of each speaker by removing FS2 and wiring directly from the input to one pad where FS2 had been mounted ~ Pink wire in picture

I also removed "half" of each parallel resistor R1 and R2 to restore some input impedance at low frequencies and removed T1 because it could operate and short the amplifier although I doubt it would ever have operated

In the picture above there is a small wax covered PCB above the mains switch this is to mount the neon bulb marked N1 on the schematic ~ Early builds of the ESL63 had a small hole drilled near the mains switch with a rubber bung that could be removed to view the neon which should flash about once a second if the HT and panel leakage are correct

In the picture above there is a small wax covered PCB above the mains switch this is to mount the neon bulb marked N1 on the schematic ~ Early builds of the ESL63 had a small hole drilled near the mains switch with a rubber bung that could be removed to view the neon which should flash about once a second if the HT and panel leakage are correct

According to IAG the crowbar circuit with T1 is to prevent a fire if the panels arc ~ It is not to protect the speakers or the amplifier it is to prevent the amplifier providing enough energy to start and maintain a fire if the panels arc ~ The HT is not switched off during arcing so it is assumed there is not enough energy there alone to sustain a fire

ESL-57s did not have fire protection so it must be a perceived problem with the ESL-63 and most likely because the intended use is with much higher input powers ~ The ESL-57 was made at the time of the 15W QUAD II but I could not see my ESL-63 loudspeakers would catch fire so the changes above were made and used for a few years

THE CHANGES SOUNDED GOOD ~ UNTIL !

Once again the persistent fault was back ~ I was tempted to next remove the diode clamp protection from each speaker but decided instead to remove the 1.5µF capacitors that IAG service had not been aware of ~ What I actually did was swap the capacitors because the one from the faulty speaker had a black patch on top

Initial listening following the C14 swap was as before ~ I was enjoying the ESL 63s with the R15 C25 and FS2 bypassed ~ The bass appeared deeper ~ probably due to the series resistance giving effective current drive but more importantly the response to transients was so much better ~ Then once again the persistent fault came back

But this time on the other speaker so it looked like the black patch C14 capacitor was to blame ~ I was relieved but also very annoyed that it had taken 3 expensive returns to QUAD and IAG and then a further 7 months to find a faulty capacitor that perhaps need not have been fitted anyhow

I was so annoyed that I took the only action an enraged Englishman could take ~ I sat down and wrote a letter ~ enclosing the two C14 capacitors hoping that at least I would get an apology from IAG service department and that they would test them and review their use in the QUAD ESL63 Loudspeaker

After several months listening to the ESL-63s with C14s changed to Philips orange 1.5µF 250V I decided to undo the other modifications because I may wish to sell them one day and it would be best if they were serviceable using the manufacturer data! ~ Also after several months I had still not received a reply from Rob Flain at IAG so I gave him a call

I asked Rob if he had received my letter and if he had shown the capacitors ~ that had cost me so much time and money over the years ~ to the accuntant who was then the managing director of IAG Service ~ He had shown my letter and the capacitors to Tim Harris who just laughed and threw them in the bin saying 'what does he expect these are years old' ~ No the faulty part was less than 6 months old when it failed ~ the years were spent finding the problem

Yes Mr Harris the faulty capacitor was "years old" and it was probably faulty when fitted in 1996 and on 3 costly occasions the IAG service department could not locate the problem ~ Even when I asked about the capacitors I was told nobody knew why they were fitted to my speakers as they were not on the schematic they used and nobody left in the service department fully understood how the design worked

Despite the long drawn out issue with my speakers I would like to thank Rob Flain and some of his staff who I am sure could provide a much better service without rocket polishers like Tim Harris running the show and I realise the fault was an odd and intermittent one but the fact is ~ IAG Service is no longer QUAD ~ even if some of the faces are the same

If the ignorance and arrogance toward loyal customers displayed by senior IAG managers propagates and if they continue simply buying in designs with little in house knowledge of how the products function then I guess they are just another 'me too' Hi-Fi manufacturer as indicated by the 77 series onward and their good value but mediocre box speakers are certainly not the 'Best of British' like the ESL57 and ESL63 or even the 988 once were

DECEMBER 2018

My ESL63s had been stored in my sons bedroom while he was a way at university and I wanted to listen to them again so I set them up in the lounge only to find that one of them was making a ticking and sometimes 'arcing' noise and guess which one ? ~ The unit that had the mid panel changed by QUAD was not at all well . . .

During a phone call to Rob Flain in 2008 he had explained that although the apparently damaged mid panel had been replaced the speakers as a pair no longer met the required cancellation criterion which ensures they are essentially matched for level and phase across the audio frequency band

After soak testing my speakers for longer than usual IAG had made a test where they reverse the input to one speaker of a pair and drive both with a Maximum Length Sequence System Analyser [MLSSA] signal and check that a particular level of acoustic cancellation can be achieved between the speakers when facing each other

My speakers were not returned for several weeks but after further 'rework' IAG decided the cancellation was sufficient and returned them to me looking good on the outside ~ The recurrence of the original fault in January 2009 had led me to only look in the base and end up swapping and then changing the mystery C14s

Now in December 2018 after 10 years working well I was looking at the inside of the ESL63 that IAG had worked on and this time at the panels with the dust covers removed ~ I could not send them back to IAG after posting these comments ~ as truthful and as they are ~ so decided to investigate the ticking noise myself . . .

What I found was a usual problem where the glue holding the PCB stator plates to the 'plastic' frame had deteriorated and the panels were loose and almost touching ~ Because it was winter in the UK the air was damp and the ticking noise was due to the HT leaking to the stator but luckily the Mylar membrane charged by the HT was not damaged

What I also found was the Mid panel fitted by IAG in 2008 had a frame with ribs more than 10% wider than those originally fitted in 1996 and the mounting hole features made this panel sit about 2mm further forward than the others ~ Was this the reason the MLSSA test failed ? ~ cancellation of the higher frequencies would likely be affected

" And though you're not my enemy ~ I like things like they used to be "

![[keith-snook.info]](/stuff/keith-info-xmas.png)